Strumenti

Siemens Ultramat 5E and CO2 measurements

NDIR analyzer (Siemens Ultramat 5E) used in Lampedusa for CO2 monitoring

Sampling technique: air samples at Lampedusa Station are collected each Friday in two pairs of 2-L glass flasks. During the sampling procedure the atmospheric

air is collected through a viton pipe by means of an oil free piston pump, flows through a magnesium perchlorate water vapour trap, and is pumped in a 2 L glass flask

at a pressure of 3 bar. The flask valve has viton o-rings. Prior to the air sampling, flasks are emptied to about 5×10-2 mbar with a two-stage rotary

vacuum pump to reduce the presence of resident impurities, and ambient air is flushed several times before collection.

Measurement technique: CO2 concentration has been determined using a NDIR analyzer (Siemens Ultramat 5E). During the measurement, filtered air

is dried by a Permapure Nafion dryer (PD-1000-24SS) to a dew-point of about -40°C. Residual water vapor is removed by means of an ethanol cold trap at -70°C.

All the measuring gases and sampled air fluxes are regulated by a mass flow controller which maintains a stable and laminar flux at 300 cm3 min-1 through the measuring cell.

The system, that allows the determination of the CO2 concentration with an accuracy of about 0.1 ppmv, has been operational since 1992 at the Casaccia Laboratory (42.1°N, 12.3°E) of ENEA for the analysis of the weekly flask samples. In 1998 the system was installed at Lampedusa, where an aspiration pump allows the collection of atmospheric air from the top of a 10 m meteorological tower, and the continuous monitoring of carbon dioxide concentration. The CO2 weekly flask program is performed in parallel with continuous measurements since 1999; the combined analysis of the two data series is in progress.

All the measuring gases and sampled air fluxes are regulated by a mass flow controller which maintains a stable and laminar flux at 300 cm3 min-1 through the measuring cell.

The system, that allows the determination of the CO2 concentration with an accuracy of about 0.1 ppmv, has been operational since 1992 at the Casaccia Laboratory (42.1°N, 12.3°E) of ENEA for the analysis of the weekly flask samples. In 1998 the system was installed at Lampedusa, where an aspiration pump allows the collection of atmospheric air from the top of a 10 m meteorological tower, and the continuous monitoring of carbon dioxide concentration. The CO2 weekly flask program is performed in parallel with continuous measurements since 1999; the combined analysis of the two data series is in progress.

Calibration: The relative concentration is referred to an absolute scale through the following procedure: the gases from two cylinders, containing known amounts

of CO2, are used as working standards during the routine operations; their concentration is measured every 3 h by the same system, providing two extrema

for the linear response interval of the analyser. Eight reference cylinders at known CO2 concentration, provided by the Climate Monitoring and Diagnostic

Laboratory (CMDL) at the National Oceanic and Atmospheric Administration (NOAA) and referred to the World Meteorological Organization scale, are used to calibrate

the working standards once a week. Standards provided by the Central Calibration Laboratory of the Scripps Institute of Oceanography (SIO), La Jolla, California, were used

before 2000. A cross check of the two sets of reference standards has shown that a very good agreement exists, and no correction to the measurements carried out

prior to 2000 need be applied. The CO2 concentration of the eight reference cylinders has been determined by comparison with primary standards,

whose concentration was measured by an absolute method.

Our group participated in several round-robin tests carried out by the WMO to verify the consistency among different laboratories throughout the world. In each test,

a set of three cylinders of air with unknown carbon dioxide concentrations were circulated and independently determined by the different laboratories. In the first

round-robin experiment (1991) the average difference among the CO2 concentrations measured at ENEA and those performed at the Scripps Institute of

Oceanography was 0.03 ppmv (the reference standards were supplied by SIO at that time). In the second round-robin test of 1999, when standards from NOAA were used,

the average difference between the ENEA and NOAA determinations was -0.14 ppmv. Results from the 2002 round robin test are not yet available.

Mode of operation of Ultramat 5E

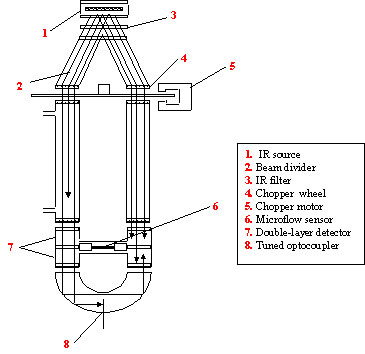

Functioning scheme of Ultramat 5E

Asymmetric molecules such as CO2 and SO2 are capable of absorbing infrared radiation owing to their electrical dipole moment.

The radiation absorbed is converted into heat. A radiation source (1) which can be moved for balancing the system is heated to about 700°C to emit infrared radiation,

which is divided into two identical beams (measuring and reference beam) in the beam divider (2). This is also used as the filter cell.

Whereas the reference beam reaches the right-hand side of the receiver chamber (7), the measuring beam passes the sample cell through which sample gas flow and

reaches the left-hand side of the receiver chamber at a lower energy state depending on the concentration of the sample gas. The receiver chambers are mostly

filled with a specific concentration of the gas to be detected.

Owing to the different radiation intensities, the gas on both sides of the receiver chamber heats up differently so that a pressure difference and thus an equalizing

flow in the connecting duct (6) are obtained. As a chopper wheel (4) rotating between the beam divider and the analyzer cell interrupts both beams periodically and

in opposite cycles, the flow of gas starts pulsating.

A microflow sensor (6) in the connecting duct consisting of two low-resistance nickel wire grids in close proximity and heated up to approximately 100°C is capable

of measuring this flow because one of the system cools down somewhat when the gas flows, whereas the opposite system heats up.

Both grids are connected to form a Wheatstone bridge whose diagonal supplies an AC voltage propotional to the pulsed flow. This voltage is amplified and measured.